|

| LEADER OF ELECTROLYSIS TECHNOLOGY |

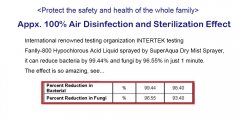

Approximate 100% Air Disinfection and Sterilization Effect

- Fanslly-800 Sterilization Test Report

- Approximate 100% Air Disinfection and Sterilization Effect

International renowned testing organization INTERTEK testing Fanslly-800 Hypochlorous Acid Liquid sprayed by SuperAqua Dry Mist Sprayer, it can reduce bacteria by 99.44% and fungi by 96.55% in just 1 minute. The effect is so amazing, see. - SuperAqua versus Epidemic Prevention

- Super Aqua Products for Disinfection

Latest News

-

Anti-Epidemic Fanslly Donate Fans...

The epidemic alert has lowered down to level 2 would cause increase demand on sterlizer especially in public venue and household, ...

SGS: Skin-friendly Hypochlorous Ac...

There are so many hypochlorous acid products in the market, how to choose? One is safe to body, and the other is...

Sanjay Dutt, Super Aqua's user

Sanjay Dutt, the Indian award winning movie star, met SuperAqua's epidemic prevention in year 2020. Noted on Fanslly-800...

Alkaline Ionized Water

Alkaline ionized water is alkaline water produced by an alkaline ionized water device (a.k.a. alkaline ionized water generator) from raw water directly and also electrolyzed reduce water known to the public. Alkaline ionized water is scientifically defined as the “weak-base low-voltage micro-molecule drinking water” (or the “reductive water” in Japan).

Super Aqua new-generation sterilization technique

The 100% hypochlorous-acid liquid is the core technique first developed by Mr.Tatsuo Okazaki, President of Okazaki Manufacture Company (OMCO) and a revolutionary product changing the history of sterilization and contributing to the Earth as well as human and environmental health.

OEM/ODM equipment

Superb background for electrolysis technologies and 1,000 patents in 40 years

Super Aqua follows a customer’s expectations or demands to design customized series of products: Household electrolyzers series (with filters included), commercial electrolyzers series, electrolyzed hypochlorous-acid liquid generator series, and ancillary equipment series.

鹼性離子水

Alan's comments for machine problem

Electrolysis Machine & Quality Problems

Following is the writing from a person who with experiences of 15 years in the alkaline ion water industry. He met and learned from his real experiences----. For avoid damages to others reputations he used " XX " instead of name:

With regards to the other equipment that you discussed, and you stated that the price are much cheaper.

You correctly stated that we have been around for a long time. I have personally been involved in this industry for 15 years. I like to think that I know the market extremely well, in particular concerning the products I sell such as the commercial unit.

I know for sure that there are very few commercial units available on the market. I had mentioned in my previous e-mail, a company by the name of XXXXX Trade who promote their products extensively on the Internet.

They promote a range of units- the XX 1000-XX 5000. The number relates to the volume of liters per hour that the units are capable of producing. They range in price from about $20,000 to about $35,000.

They are manufactured in China.

There is a Chinese Company called X-XXXX who market 2 machines on the Internet, the XXX 1000, and the XXX3000, which are $20,000 and $28,000 respectively.

These are manufactured in China also.

With regards to the XXXXX units, these units are not designed to bottle drinking water. They are designed to produce the antimicrobial water, which measures about 2.5 pH, and the high alkaline water, which measures at about 11 pH. This is achieved with the addition of salt.

The issues here are that no one should drink 11 pH water, in doing so, this would interfere with the body's natural mechanism to produce hypochlorous acid to aid digestion.

The water would taste salty.

The electrodes or cells of the unit will oxidize extremely quickly under high production.

With regards to the XXXXX Trade products, I know of at least six of these units that have been sold within the United States and also in the Caribbean.

In every case, these units have not worked properly, or have broken down. The units installed in the Caribbean in bottling plants there broke down after about four months. There were three separate units in 3 separate bottling plants on three separate islands, and they all broke down.

This was due to the hardness of the water, and the inability of the units to clean themselves effectively, and thus the electrodes became heavily calcified causing breakdown.

XXXXX Trade refused to take any responsibility. They refused to send out an engineer, even though the units were still under warranty. They refused to give a refund.

Two of the units in the United States had similar problems. As soon as the electrolysis chamber began to get clogged, the breakers were tripped and the unit did not work.

Once again, the supplier refused to take any responsibility, again they were still under warranty, and again they refused to give a refund.

Within the past week I have learned of another unit that has not worked for two years, and they have had no success in having their problem addressed by XXXXX Trade.

The last unit sold is another example of their poor business practices. The company purchased the equipment based on the fact that they were told by XXX XXbados, owner of XXXXX Trade, that the water produced by the unit would have a shelf life of two years.

When the company found out from XXXXX Trades engineer that this was a deliberate lie, they wanted to return the equipment, UNUSED, and get their money back. Once again, they were refused.

They have now taken out a lawsuit against XXXXX Trade, and it is quite likely that this will become a " class action" lawsuit involving many people.

Apparently, it is not just the commercial ionizers that this happens with this company. They have an extremely poor reputation within the industry here.

As it is a relatively small industry, we tend to know each other. We know the good guys and we know the bad guys.

Unfortunately, there are more than a few bad guys in our business, and it does seem to attract them! I have met too many of them in my life!

I am an honest businessman, and I only want to do honest business with honest people. The company that I represent is an honest manufacturer, who I can trust 100% to support my company and the product in every way.

While I don't deny this product is expensive, it is due to the quality of the product and the reliability of its technology.

If you are familiar with the cleaning mechanism off the residential home unit, you will know that once the unit is shut down it then goes into cleaning mode.

You are possibly aware that the methodology of cleaning is that the polarity of the electrodes is reversed. This typically takes about 30 seconds.

You also know that these units cannot be operated for longer than about 30 minutes continuously at the most. Any longer that this and they risk overheating, and damaging the transformer.

Imagine then the demands of a bottling facility, where the units are constantly in use for up to18 hours a day, sometimes seven days a week.

The units are engineered to be constantly cleaning themselves as they operate. The waste water will discharge from waste water hose and not mix into Alkaline ion water tank.

This is the beauty of the technology. it is trouble-free.

The equipment is an extremely important purchase, which has to be reliable, and last for many years to come.

Kirin Beverage and Taiwan Salt and other big beverage companies are the users and most of them are the market leader. The technology and industry records are unique in the world.

By Alan Ogievle

References:

How to improve from NDX-XXXX?

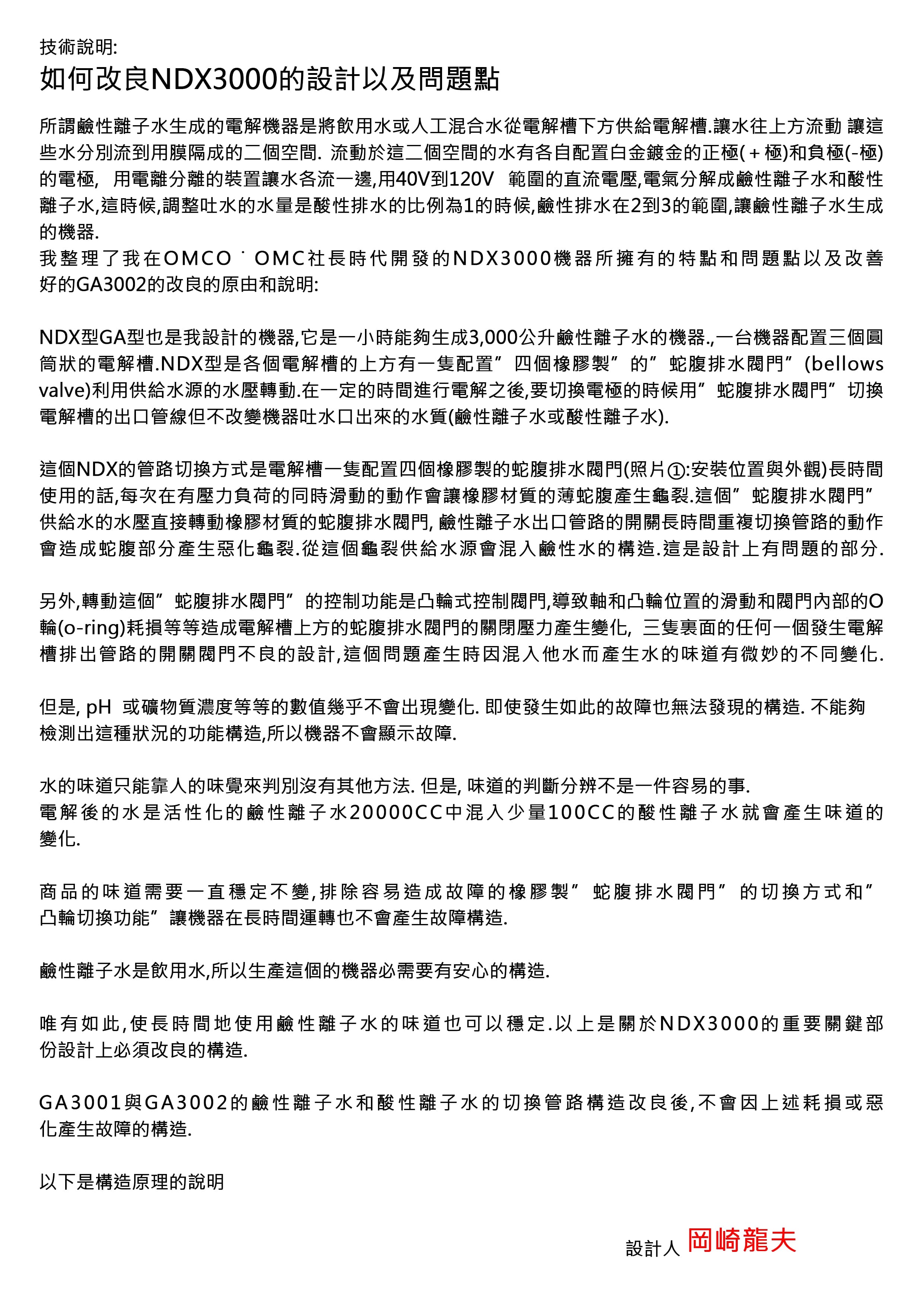

Technical Instruction:

How to improve the Design and Problems of NDX-3000?

So called alkaline ionized water electrolysis generator has the electrolytic chambers which use drinking water or artificial mixed water supplying the water from bottom and upflow into two rooms separately by the membrane. The water circulating into this two rooms which has the platinum (anode) and (cathode) electrodes formed into alkaline ionized water and acidic ionized water. By using electricity device to separately the water into individually, with DC voltages between 40 V and 120V and The ratio of water volume on acidic ionized water and alkaline ionized water, is at about 1 (acidic ionized water) and 2~3 (alkaline ionized water) which the alkaline ionized water machine is.

I have sorted out the problems of NDX-XXXX which designed and manufactured when I was the President of OMCO (Okazaki Manufacture Co) and the reasons to develop GA-3000, the modified version herein, are summarized and listed as follows.

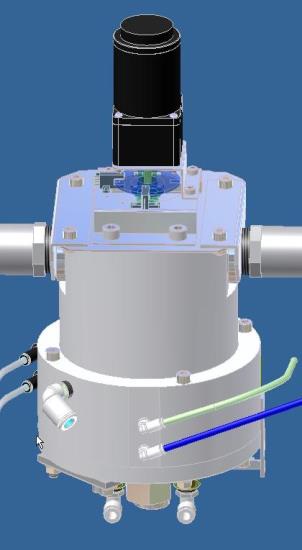

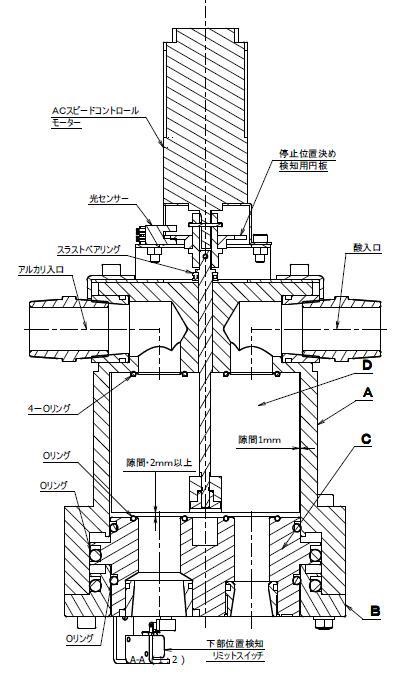

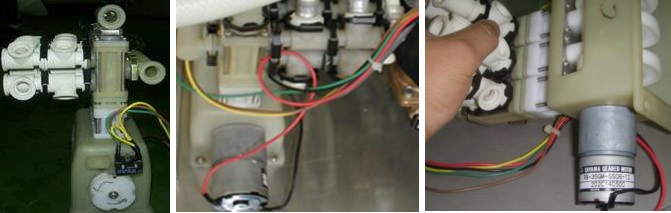

The Model of NDX and GA machines were my design which produces 3,000 litters of alkaline ionized water per hour and is provided with three cylindrical electrolytic chambers. On each electrolytic chamber the NDX-XXXX has installed with four rubber bellows valves which are driven to rotations by the water pressure.

By the certain time electrolysis procedure, the outlet lines of an electrolytic chamber will be switched via bellows valves but the quality of acidic/alkaline ionized water discharged from the water outlets of the electrolysis chambers keeps unchanged

The method of switch valves of NDX-XXXX is , the thin rubber of four bellows valves on each electrolytic chamber (Photo 1: their positions and exteriors) suffered from the water pressure loads after long period of time which will be caused the crack and water leakage. When the rubber bellows valves under water pressure are rotated repeatedly and the switched on the outlet of alkaline ionized water which caused the rubber bellows valves are worsened and cracks which the alkaline ionized water is mixed with the supplied of feed water. This is the defective of structural design on NDX-XXXX.

Moreover, the cam-type control valve has dominating rotations of bellows valves aggravates the deviation of the sliding cam from the shaft and further the abrasion of internal O-rings, all of which may change water pressures applied to close bellows valves on each of three electrolytic chambers on the outlet lines. In defective of this problem, the taste of water will be different slightly when ionized water is mixed with other water.

However, the attributes such as pH values and concentrations of minerals are almost unchanged even if the above problem occurs in NDX-XXXX which fails to detect and shows fault conditions.

The taste of water which depends on a person’s palate only is difficultly differentiated.

In this regard, the taste of electrolyzed water, which consists of activated alkaline ionized water and acidic ionized water, is changed when 100 cc of acidic ionized water is added into 2,000 cc of alkaline ionized water.

For commercialized bottled water, the taste of water should be kept constant. Accordingly, the drawbacks such as troublesome rubber bellows valves for switching water tubes based on a cam should be improved in the electrolysis machine for long-term performance. To produce bottled alkaline ionized water, the electrolysis machine should be reliable on structure. As such, the taste of water from the equipment on manufacture of alkaline ionized water shall be keeping the constant for long time operation. Therefore, the design of some critical components in Model NDX-XXXX needs to be modified.

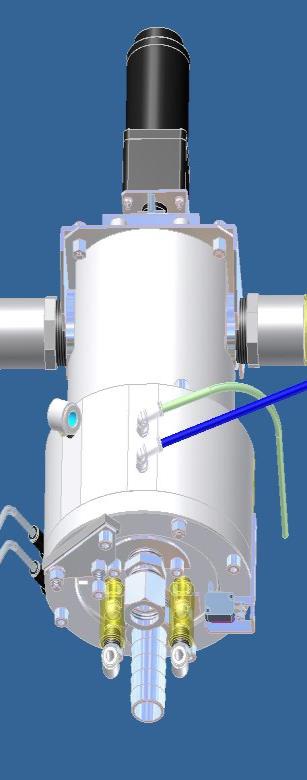

The structure to switch water tubes on alkaline ionized water and acidic ionized water in Model of GA-3001 and GA-3002 has been improved without any troubles attributed to above abrasion or deterioration.

The details for the theory and the structure of Model GA-3001 and GA-3002 are presented as follows.

By Mr. Tatsuo Okazaki, The Machine Designer

The Valves in Model NDX-XXXX on Switching Water Tubes

|

|

Photo 2: Cam-type control valve to switch bellows valves. Position of the electric switch to regulate the control valve (left); complex tubing (center); cam (right) |

The Modified Valve on the Switching Water Tubes

|

|

The Display panel of the photo sensor disc on the rotary valve (left); water outlet at the bottom (right) |

|

As shown in the sectional view of a rotary valve (left), the rotary valve D is installed inside the switching valve body A and the drawing portion C under water pressure is moved flexibly. The O-rings stressfully contact two outlets of alkaline ionized water and acidic ionized water on the switching valve body A to avoid leakage or mixing of water from the rotary valve D and the switching valve body A. The four O-rings mounted on the drawing portion C underneath are fixed by supplied water so that both the drawing portion C and two lines at the rotary valve D communicate with each other at the outlet of the drawing portion C |

| The outlets of alkaline ionized water and acidic ionized water from the electrolytic chamber are modified. Furthermore, the rotary valve D is rotated so that the quality of water from the electrolytic machine is kept homogeneous.

When the rotary valve D is moved downward, some gaps are created and further maintained around the rotary valve D for switching water tubes. After the water tubes are integrated with the rotary valve D and detected by the photo sensor disc at the correct position, the running of the rotary motor is suspended and the drawing portion C from which no fluid leaks is compressed by supplied water. During switching of water tubes, all O-rings which are designed to not contact components will not be worn. Moreover, the rotary motor will not sustain excessive load because of gaps around the rotary valve which is being activated. According to this design, the rotary valve which is being activated for switching water tubes does not contact components, no fluid leaks from O-rings which are compressed with the drawing portion C enabled, and no O-ring is worn. It can be seen from the modified rotary valve that all drawbacks in Model NDX-3000 are overcome |

参考附件:

Golden Alkalizer Technology and Merits

Golden Alkalizer@Technology and Merits

The unique technology for electrolysis alkaline ionized water and other functional water :

Golden Alkalizer@ electrolysis technology has dated back for 40 years researches and with some 1,000 industrial patents. We felt proud of our electrolysis technology is some top in the world.

The Golden Alkalizer Industrial electrolysis machine has following merits:

1. For Mass Productions:

Golden Alkalizer ( GA ) industrial electrolysis machine is the newest and largest single electrolysis machine in the world which designed for the mass manufacture purpose at the bottled water or beverage plants. The GA machine is possible produce 3 tons of alkaline ionized water and some 1 tons of acidic ionized water per hour.

2. High Electrolysis Efficiency:

One GA-3000/GA-3002 has 3 set of unique round electrolysis chambers which the electrolysis efficiency is 3.14 times than flat type machine. ( the Circumference is 3.14 times of diameter ). The electrolysis is very fast for producing the alkaline ionized water with high concentration with good pH level.

3. Auto Reverse Wash Technology(patented):

Golden Alkalizer has the patented auto switch valves which upon the reverses cleaning wash the water valves will be auto switched, The water way will be also auto switched so that the waste water will be discharging from the waste water pipe. The waste water and the acidic ionized water will not mix into the alkaline ion water tank.

Golden Alkalizer has the round cell chambers technology which is easily for reverse cleaning wash so that the minerals or calcium of water will be not clogging in the membrane or chambers. So the the alkaline ionized water is good and the pH of water is stable.

4. Auto Manufacturing Technology:

GA machine were designed for auto and mass manufacture purpose. By connected with the Control Box (optional) and the relays of all GA electrolysis machines and the system can be auto operating for mass manufacturing.

By installed the pH detecting sensor (optional) with the GA machine system so the pH of water can be detecting on line. If the pH of water is not expected then the system will discharge the water via waster water pipes

The GA machines has 7 steps ( 0-6) of adjuster at different electricity current so that manufacturing the pH level of alkaline ionized water expected.

5. Electrolysis chamber exchange alert:

The GA machine has the life of electrolysis chamber exchange alert lamp so that remind electrolysis chamber replacing on time for ensure good quality of production.

6. Long Hours Operation is possible

The industrial electrolysis technology are designed for factory mass production purpose.

The GA designed for industrial purpose and it's possible operate at some 20 hours/day.

7. Tasty Water Technology

Golden Alkalizer@ has the special technology which minerals ion can get through membrane for alkaline ionized water which the alkaline ionized water is more tasty and healthier, mild and delicious. Even at the high pH of water but the taste of water is mild and delicious.

8. Saving Water technology:

The ratio of alkaline ion water is some 3/4 and acidic water is 1/4 which saving 500L/hour on the feed water per hour than previous model. For long terms operation it is much more saving water resource for our clients and it is green technology. We can instruct our clients for good use of acidic ionized water or for reuse of acidic ionized water.

9. Abundant Commercial Records:

Our technology and our management team has good experience of installation at plant with abundant commercial records in the world. Most of our clients are success and are the market leader in their area.

Some top technology in the world, We are your best partner for your functional water business!

Bottled Alkaline Ionized Water Products (Included Okazaki Technology Applied )

Bottled Alkaline Ionized Water Included Okazaki' technology Applied Products

Some customers’ bottled alkaline ionized water products are shown as follows. The proprietary industrious design and equipment from our technical team have been adopted by major beverage manufacturers in Asia and available in the market for years. Our products are valued by customers and consumers because healthy concept water and bottled functional water are the current and tendency of the global bottled water market in the future!

客戶瓶裝鹼性離子水商品

kirin.png

http://www.superaquaholding.com/images/products/client/kirin.png

Kirin Beverage Alkaline Ion Water

Kirin Beverage Alkaline Ion Water, Japan (500ML/2L)

http://localhost/superaqua/images/products/client/Kirin_Beverage_Alkaline_Ion_Water.jpg

Watsons Alkaline Water 9.0

Watsons Alkaline Water 9.0

http://www.superaquaholding.com/images/products/client/Watsons_Alkaline_Water_9.0.jpg

SuPau_Alkaline_Ionized_Water_20in.jpg

http://www.superaquaholding.com/images/products/client/SuPau_Alkaline_Ionized_Water_20in.jpg

Taiwan Vitalon SuPau Alkaline Ionized Water

Taiwan Vitalon SuPau Alkaline Ionized Water

http://www.superaquaholding.com/images/products/client/SuPau_Alkaline_Ionized_Water.jpg

Taiwan_Salt_Alkaline_Ion_Water_2.jpg

http://www.superaquaholding.com/images/products/client/Taiwan_Salt_Alkaline_Ion_Water_2.jpg

Taiwan Salt Ocean Alkaline Ion Water

Taiwan Salt Ocean Alkaline Ion Water, Taiwan

http://localhost/superaqua/images/products/client/Taiwan_Salt_Ocean_Alkaline_Ion_Water.jpg

Taiwan Salt Sport Ionized Water

Taiwan Salt Sport Ionized Water

http://localhost/superaqua/images/products/client/Taiwan_Salt_Sport_Ionized_Water.jpg

Taiwan Salt Beauty Toner

Taiwan Salt Beauty Toner ( made by acidic water )

http://localhost/superaqua/images/products/client/Taiwan_Salt_Beauty_Toner.jpg

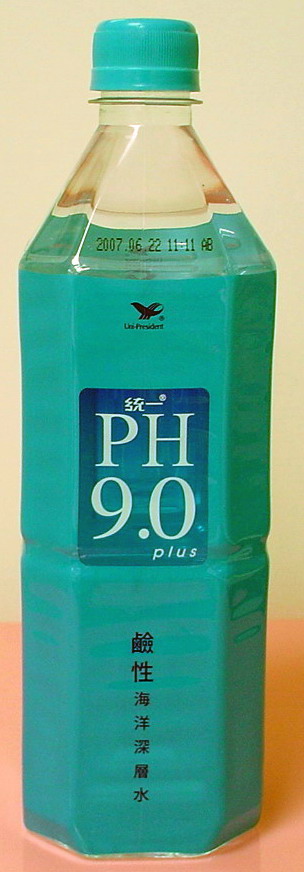

PH9.0_Alkaline_ion_Water_2.png

http://www.superaquaholding.com/images/products/client/PH9.0_Alkaline_ion_Water_2.png

PH9.0 Alkaline ion Water (old label)

PH9.0 Alkaline ion Water ,Taiwan Uni-President,Taiwan (old label)

http://localhost/superaqua/images/products/client/PH9.0_Alkaline_ion_Water.jpg

Alkaqua Alkaline Ion Water

Alkaqua Alkaline Ion Water. Uni-President, China

http://localhost/superaqua/images/products/client/Uni-President_Alkaqua_Alkaline_Ion_Water.jpg

Alkaqua_4in.png

http://www.superaquaholding.com/images/products/client/Alkaqua_4in.png

Wahaha Gallon Alkaline Ion Water

Wahaha Gallon Alkaline Ion Water,China (20L)

http://www.superaquaholding.com/images/products/client/Wahaha_Gallon_Water.png

Ion_Life_19L.png

http://www.superaquaholding.com/images/products/client/Ion_Life_19L.png

Ion Life 425ml

Ion Life 425ml , Vietname

http://www.superaquaholding.com/images/products/client/Ion_Life_425ml.jpg

Ion Life 1.2L

Ion Life 1.2L, Vietnam

http://localhost/superaqua/images/products/client/Ion_Life_1_point_2L.jpg

FamilyMart Alkaline Ionized Water

FamilyMart Alkaline Ionized Water,Taiwan (850ml/1.5L/500ml)

http://www.superaquaholding.com/images/products/client/FamilyMart_alkaline_ionized_water_x3.jpg

ShuiGuanNi.png

水管你鹼性離子水

http://www.superaquaholding.com/images/products/client/ShuiGuanNi.png

Taiyen | FamilyMart | Uni-President

(左) 台鹽海洋鹼性離子水

(中) 水管你鹼性離子水

(右) 統一PH 9.0 plus 鹼性海洋深層水Taiwan Salt Alkaline Ion Water

台鹽海洋鹼性離子水

http://www.superaquaholding.com/images/products/client/Taiwan_Salt_Alkaline_Ion_Water_Photo.jpg

Taiwan Salt Alkaline Ion Water Label

台鹽海洋鹼性離子水 (瓶標)

http://www.superaquaholding.com/images/products/client/Taiwan_Salt_Alkaline_Ion_Water_Label.jpg

FamilyMart Alkaline Water

水管你鹼性離子水

http://www.superaquaholding.com/images/products/client/ShuiGuanNi_3.jpg

FamilyMart Alkaline Water Label

水管你鹼性離子水 (瓶標)

http://www.superaquaholding.com/images/products/client/ShuiGuanNi_Label.jpg

Uni-President PH 9.0 Plus Alkaline Ion Water

統一PH 9.0 plus 鹼性海洋深層水

http://www.superaquaholding.com/images/products/client/PH9.0_Alkaline_ion_Water_2.jpg

Uni-President PH 9.0 Plus Alkaline Ion Water Label

統一PH 9.0 plus 鹼性海洋深層水 (瓶標)

http://www.superaquaholding.com/images/products/client/PH9.0_Alkaline_ion_Water_Label.jpg

WELLCOME First Choice Alkaline Ion Water

WELLCOME First Choice Alkaline Ion Water,Taiwan (OEM brand)

http://www.superaquaholding.com/images/products/client/WELLCOME_First_Choice_Alkaline_Ion_Water.png

Kirin Label

Kirin (瓶標)

http://www.superaquaholding.com/images/products/client/Kirin_Label_Image.png

Ichitan_PH_PLUS_8.5_1.jpg

http://www.superaquaholding.com/images/products/client/Ichitan_PH_PLUS_8.5_1.jpg

Ichitan_PH_PLUS_8.5_2.jpg

http://www.superaquaholding.com/images/products/client/Ichitan_PH_PLUS_8.5_2.jpg

Ion_Max.jpg

Ion Max

http://www.superaquaholding.com/images/products/client/Ion_Max.jpg

Clients' bottled alkaline ionized water products (included technology applied )

Bottled Alkaline Ionized Water Products ( included Okazaki's technology applied )

Some customers’ bottled alkaline ionized water products are shown as follows. The proprietary industrious design and equipment from our technical team have been adopted by major beverage manufacturers in Asia and available in the market for years. Our products are valued by customers and consumers because healthy concept water and bottled functional water are the current and tendency of the global bottled water market in the future!

客戶瓶裝鹼性離子水商品

kirin.png

http://www.superaquaholding.com/images/products/client/kirin.png

Kirin Beverage Alkaline Ion Water

Kirin Beverage Alkaline Ion Water, Japan (500ML/2L)

http://localhost/superaqua/images/products/client/Kirin_Beverage_Alkaline_Ion_Water.jpg

Watsons Alkaline Water 9.0

Watsons Alkaline Water 9.0

http://www.superaquaholding.com/images/products/client/Watsons_Alkaline_Water_9.0.jpg

SuPau_Alkaline_Ionized_Water_20in.jpg

http://www.superaquaholding.com/images/products/client/SuPau_Alkaline_Ionized_Water_20in.jpg

Taiwan Vitalon SuPau Alkaline Ionized Water

Taiwan Vitalon SuPau Alkaline Ionized Water

http://www.superaquaholding.com/images/products/client/SuPau_Alkaline_Ionized_Water.jpg

Taiwan_Salt_Alkaline_Ion_Water_2.jpg

http://www.superaquaholding.com/images/products/client/Taiwan_Salt_Alkaline_Ion_Water_2.jpg

Taiwan Salt Ocean Alkaline Ion Water

Taiwan Salt Ocean Alkaline Ion Water, Taiwan

http://localhost/superaqua/images/products/client/Taiwan_Salt_Ocean_Alkaline_Ion_Water.jpg

Taiwan Salt Sport Ionized Water

Taiwan Salt Sport Ionized Water

http://localhost/superaqua/images/products/client/Taiwan_Salt_Sport_Ionized_Water.jpg

Taiwan Salt Beauty Toner

Taiwan Salt Beauty Toner ( made by acidic water )

http://localhost/superaqua/images/products/client/Taiwan_Salt_Beauty_Toner.jpg

PH9.0_Alkaline_ion_Water_2.png

http://www.superaquaholding.com/images/products/client/PH9.0_Alkaline_ion_Water_2.png

PH9.0 Alkaline ion Water (old label)

PH9.0 Alkaline ion Water ,Taiwan Uni-President,Taiwan (old label)

http://localhost/superaqua/images/products/client/PH9.0_Alkaline_ion_Water.jpg

Alkaqua Alkaline Ion Water

Alkaqua Alkaline Ion Water. Uni-President, China

http://localhost/superaqua/images/products/client/Uni-President_Alkaqua_Alkaline_Ion_Water.jpg

Alkaqua_4in.png

http://www.superaquaholding.com/images/products/client/Alkaqua_4in.png

Wahaha Gallon Alkaline Ion Water

Wahaha Gallon Alkaline Ion Water,China (20L)

http://www.superaquaholding.com/images/products/client/Wahaha_Gallon_Water.png

Ion_Life_19L.png

http://www.superaquaholding.com/images/products/client/Ion_Life_19L.png

Ion Life 425ml

Ion Life 425ml , Vietname

http://www.superaquaholding.com/images/products/client/Ion_Life_425ml.jpg

Ion Life 1.2L

Ion Life 1.2L, Vietnam

http://localhost/superaqua/images/products/client/Ion_Life_1_point_2L.jpg

FamilyMart Alkaline Ionized Water

FamilyMart Alkaline Ionized Water,Taiwan (850ml/1.5L/500ml)

http://www.superaquaholding.com/images/products/client/FamilyMart_alkaline_ionized_water_x3.jpg

ShuiGuanNi.png

水管你鹼性離子水

http://www.superaquaholding.com/images/products/client/ShuiGuanNi.png

Taiyen | FamilyMart | Uni-President

(左) 台鹽海洋鹼性離子水

(中) 水管你鹼性離子水

(右) 統一PH 9.0 plus 鹼性海洋深層水Taiwan Salt Alkaline Ion Water

台鹽海洋鹼性離子水

http://www.superaquaholding.com/images/products/client/Taiwan_Salt_Alkaline_Ion_Water_Photo.jpg

Taiwan Salt Alkaline Ion Water Label

台鹽海洋鹼性離子水 (瓶標)

http://www.superaquaholding.com/images/products/client/Taiwan_Salt_Alkaline_Ion_Water_Label.jpg

FamilyMart Alkaline Water

水管你鹼性離子水

http://www.superaquaholding.com/images/products/client/ShuiGuanNi_3.jpg

FamilyMart Alkaline Water Label

水管你鹼性離子水 (瓶標)

http://www.superaquaholding.com/images/products/client/ShuiGuanNi_Label.jpg

Uni-President PH 9.0 Plus Alkaline Ion Water

統一PH 9.0 plus 鹼性海洋深層水

http://www.superaquaholding.com/images/products/client/PH9.0_Alkaline_ion_Water_2.jpg

Uni-President PH 9.0 Plus Alkaline Ion Water Label

統一PH 9.0 plus 鹼性海洋深層水 (瓶標)

http://www.superaquaholding.com/images/products/client/PH9.0_Alkaline_ion_Water_Label.jpg

WELLCOME First Choice Alkaline Ion Water

WELLCOME First Choice Alkaline Ion Water,Taiwan (OEM brand)

http://www.superaquaholding.com/images/products/client/WELLCOME_First_Choice_Alkaline_Ion_Water.png

Kirin Label

Kirin (瓶標)

http://www.superaquaholding.com/images/products/client/Kirin_Label_Image.png

Ichitan_PH_PLUS_8.5_1.jpg

http://www.superaquaholding.com/images/products/client/Ichitan_PH_PLUS_8.5_1.jpg

Ichitan_PH_PLUS_8.5_2.jpg

http://www.superaquaholding.com/images/products/client/Ichitan_PH_PLUS_8.5_2.jpg

Ion_Max.jpg

Ion Max

http://www.superaquaholding.com/images/products/client/Ion_Max.jpg

Fanslly-800 Hypochlorous Acid Powder Series

Fanslly-800 Hypochlorous Acid Powder,

Easily Transform Water Become Hypochlorous Acid!!

|

|

|

|

|

| 1 gram | 2 grams | 3.2 grams | 500 grams | 1000 grams |

NMR Scientific Certification for Small-molecular Water Cluster

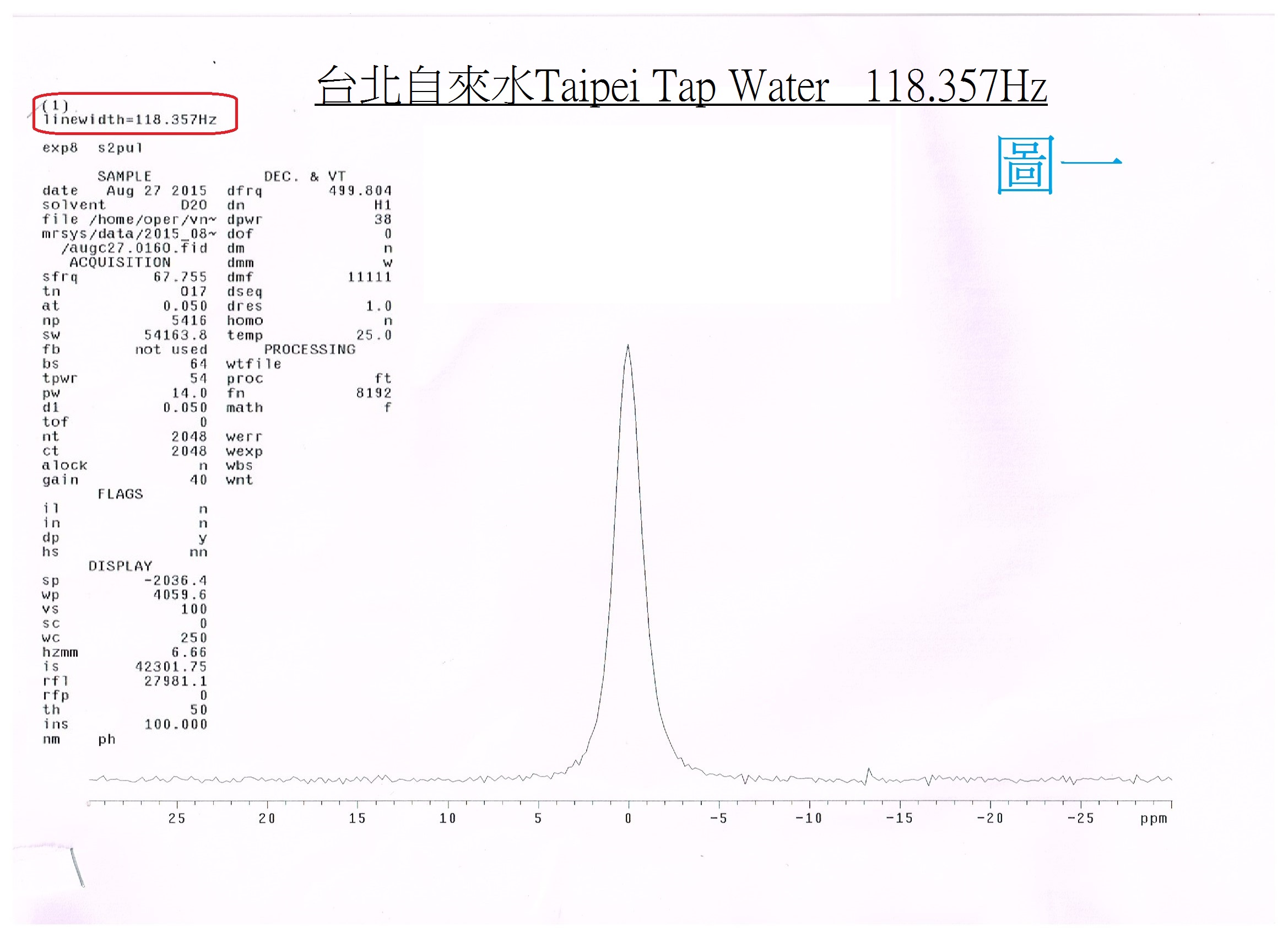

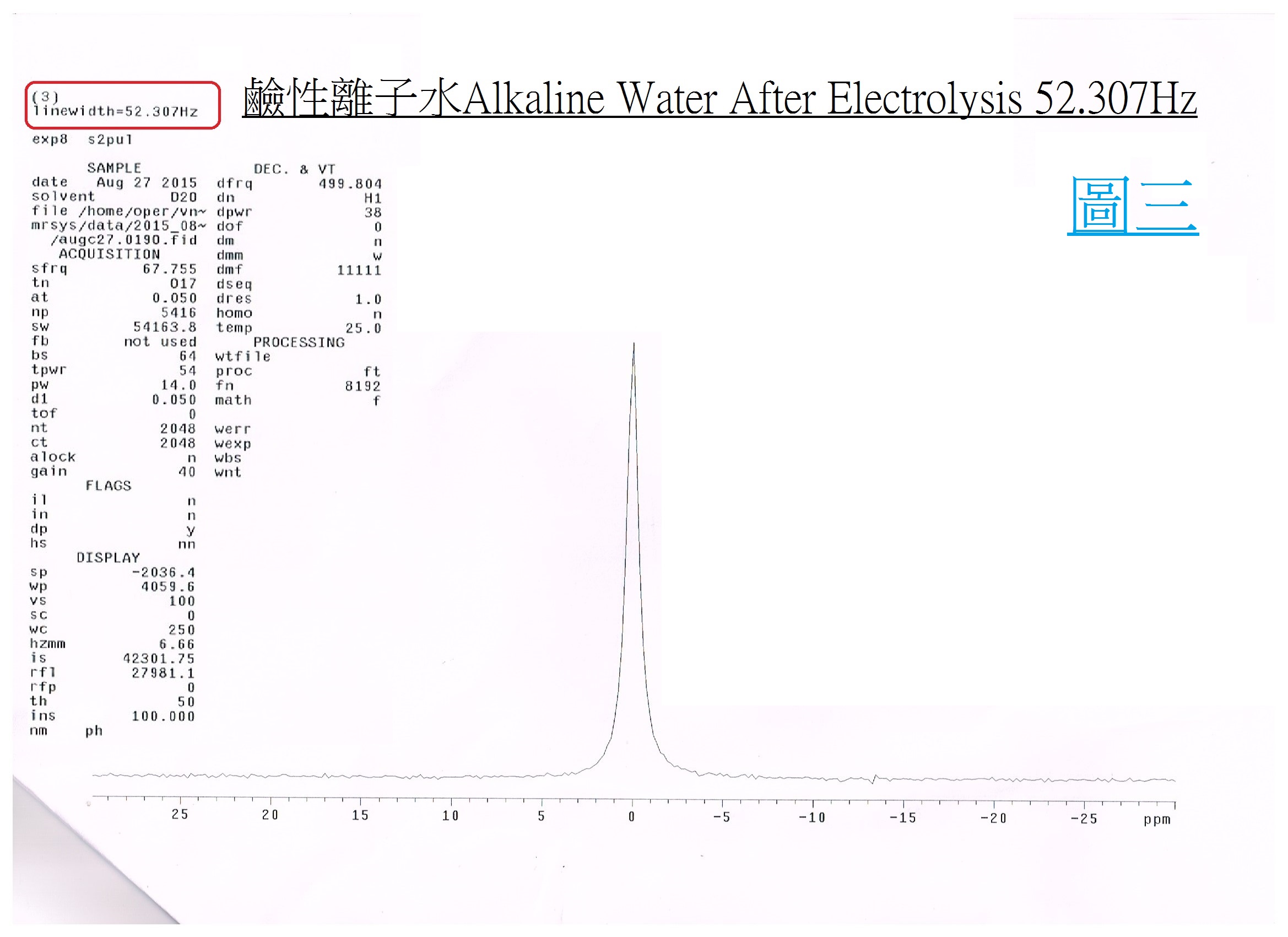

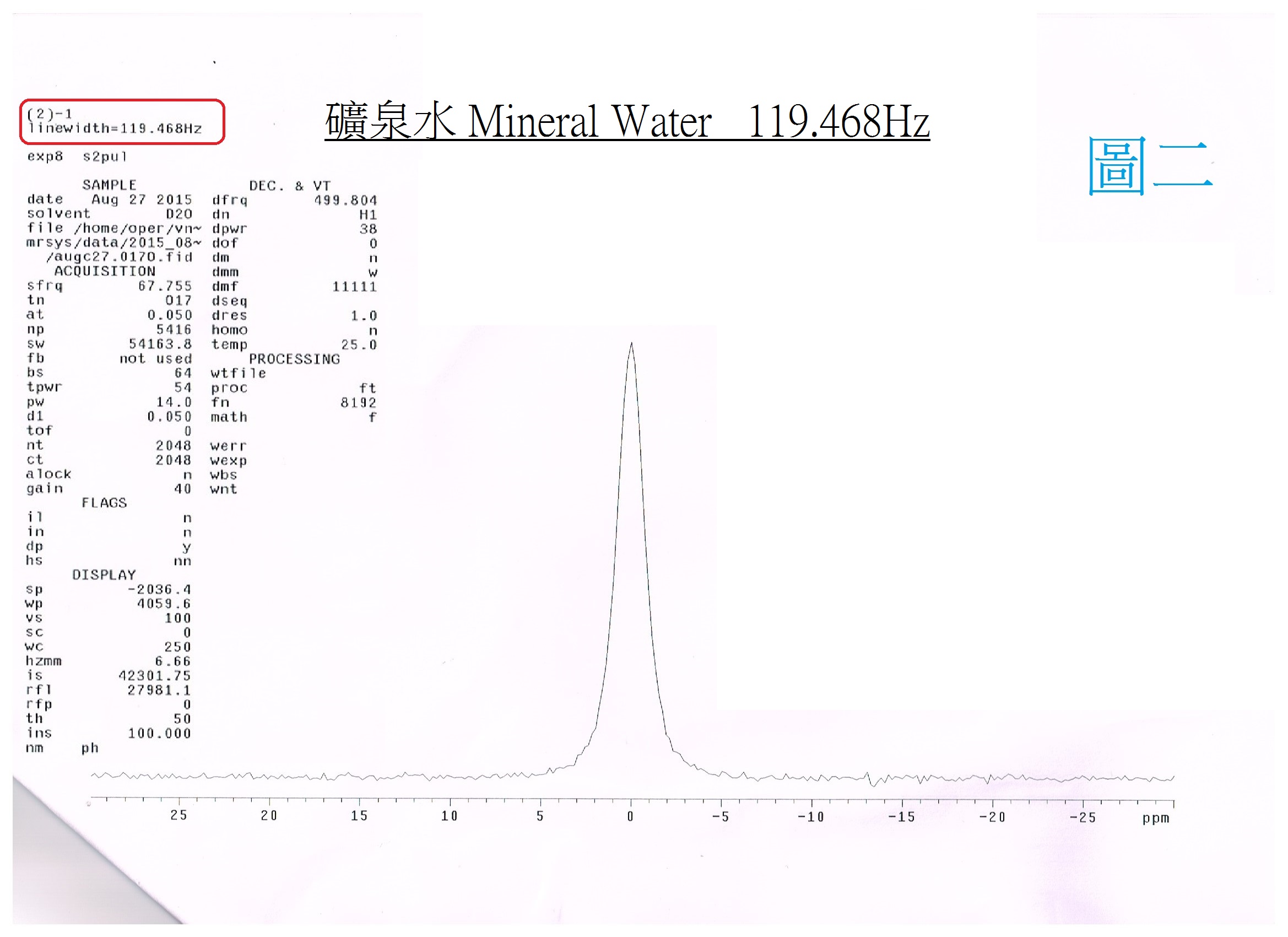

Small Cluster Water:Electrolyzed reduced water (alkaline ionized water) has been verified as small-molecular cluster water according to the NMR spectrometer. |

The alkaline ionized water is small cluster water, which can be measured by the NMR (Nuclear magnetic resonate spectrograph): the tap water is about 118Hz (PIC. 1); The mineral water is about 119Hz (PIC. 2); and the pH9 of alkaline ionized water (PIC. 3) is about 52Hz. |

|

During the electrolysis process, the water molecules will be recombined to small cluster water.

Easily absorbed by human body, the water with small cluster water is helpful for metabolism and can remove acidic substances and wastes from human body, therefore enhancing the inner environmental system, properly adjust the acidic physical condition and improve our health! |

Equipment for Alkaline Ionized Water

Technical features of Golden Alkalizer

Alkaline Ionized water: about 3,000L/hr

Acidic Ionized water: about 1,000L/hr

Comparisons of All Types of Bottled Drinking Water

|

Item Type |

Manufacturing process | pH value | Mineral | Water molecule cluster * Note 1 |

Water molecule (NMR) * Note 2 |

Taste (molecule cluster and hardness) |

Health Elements |

|---|---|---|---|---|---|---|---|

| Alkaline ionized water | (1) RO water + minerals→ electrolysis (2) natural water → electrolysis |

Alkaline (pH=9~9.5) |

Ionized minerals | 6 | Small (45Hz~55Hz) (depending on pH values) |

Palatable (Making tea or coffee, cocktail, cuisine, etc.) |

Small-molecule water active hydrogen (hydrogen) hydrogy ion Ca(OH)2 ionized minerals |

| Natural mineral water natural water |

Mountain spring groundwater |

Weak alkaline or acid (pH≒7.5) |

Natural minerals; natural minerals with trace elements |

8~12 (depending on locations and water conditions) |

94Hz (depending on locations; 80Hz (Village of Long Life)) |

Tastes depending on hardness and water molecule clusters are different from one another. | Natural minerals; trace elements |

| Mineralized drinking water | Tap water → RO water + artificial mineral | Acid (pH≒6.5) |

Pure water with artificial minerals added | 8~10 | 88Hz~90Hz in general (RO water) |

Palatable | Small-molecule water minerals |

| Pure water distilled water |

Groundwater or tap water → RO water or distillation processing |

Acid (pH≒6.0) neutral or acidic (distilled water) |

Nil | 8~10 13~15 |

Pure water: 88-90Hz; distilled water: 140Hz |

Good taste for pure water (no hardness); taste worsen for distilled water with larger molecule clusters |

It is not healthy to drink pure (distilled) water for a long period. * Note 3: The small-molecule water with little mineral is not healthy. |

|

* Note 1: Data of Kazuhiro Matsushita, JEOL |

English

English  繁體中文

繁體中文  简体中文

简体中文

Photo of Rotary valve

Photo of Rotary valve