|

| LEADER OF ELECTROLYSIS TECHNOLOGY |

You Must Succceed

Introduction of Industrial Electrolytic Alkaline Ionized Water Equipment

Technology and Testimonials

- When investing in bottled functional water and new Ion Plus functional drink products, in addition to considering industrial electrolyzers, production lines (production, manufacturing, and filling), warehousing, and logistics need to be considered and evaluated. Advertising, marketing, channels, consumer services, etc., for enterprises, it can cost at least one million US dollars to as many as tens of millions of US dollars. This is a big investment and project

- In addition, the equipment, production capacity, finance, and capital of the water plant itself are also important factors.

-

The most basic and important point is the selection of "industrial water electrolysis machines".

This is different from ordinary home appliances (TVs, refrigerators), because "industrial water electrolysis machines" are main equipment used to produce profits!

- household electrolysis machines are designed to be used at home for 30 minutes a daily usage and are not suitable for mass production in factories.

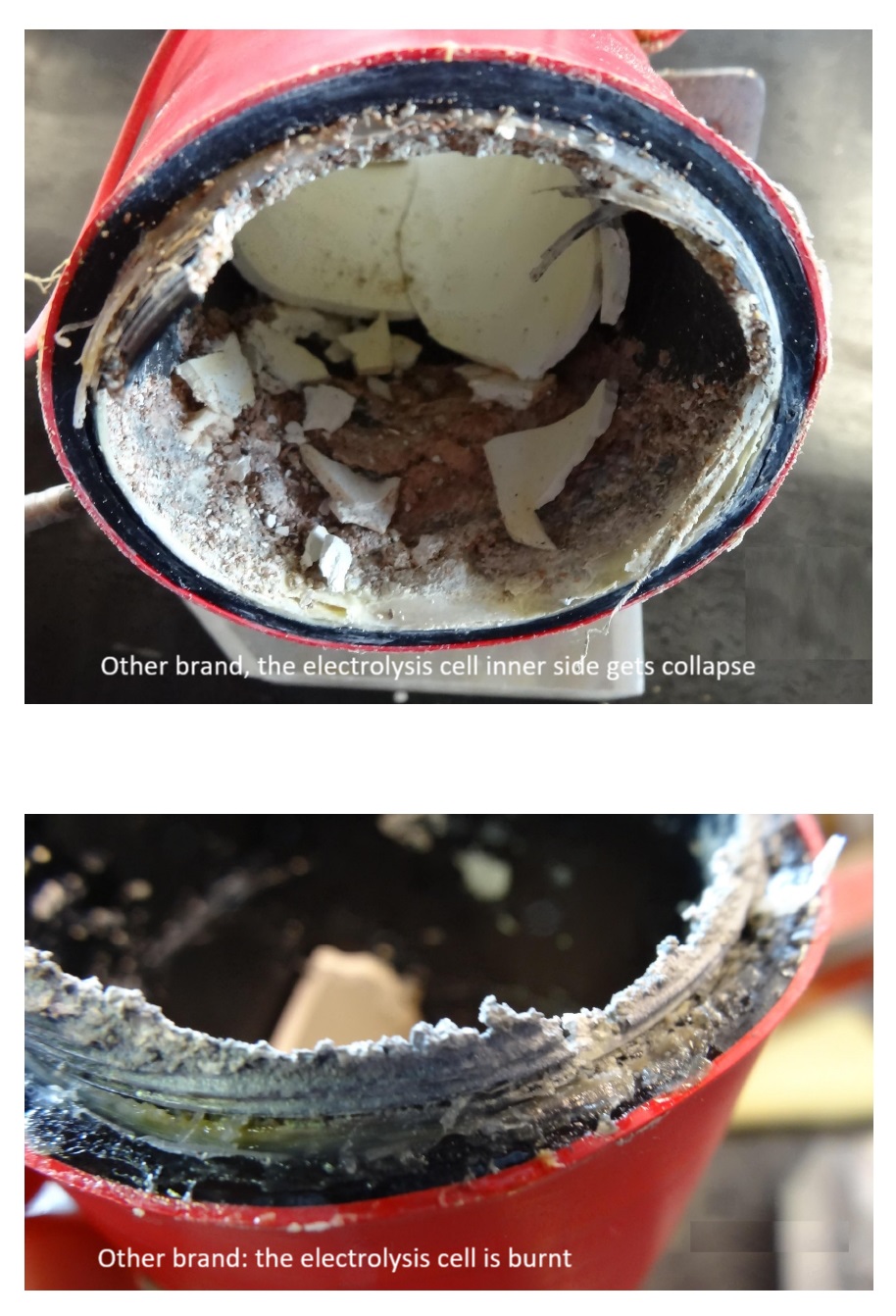

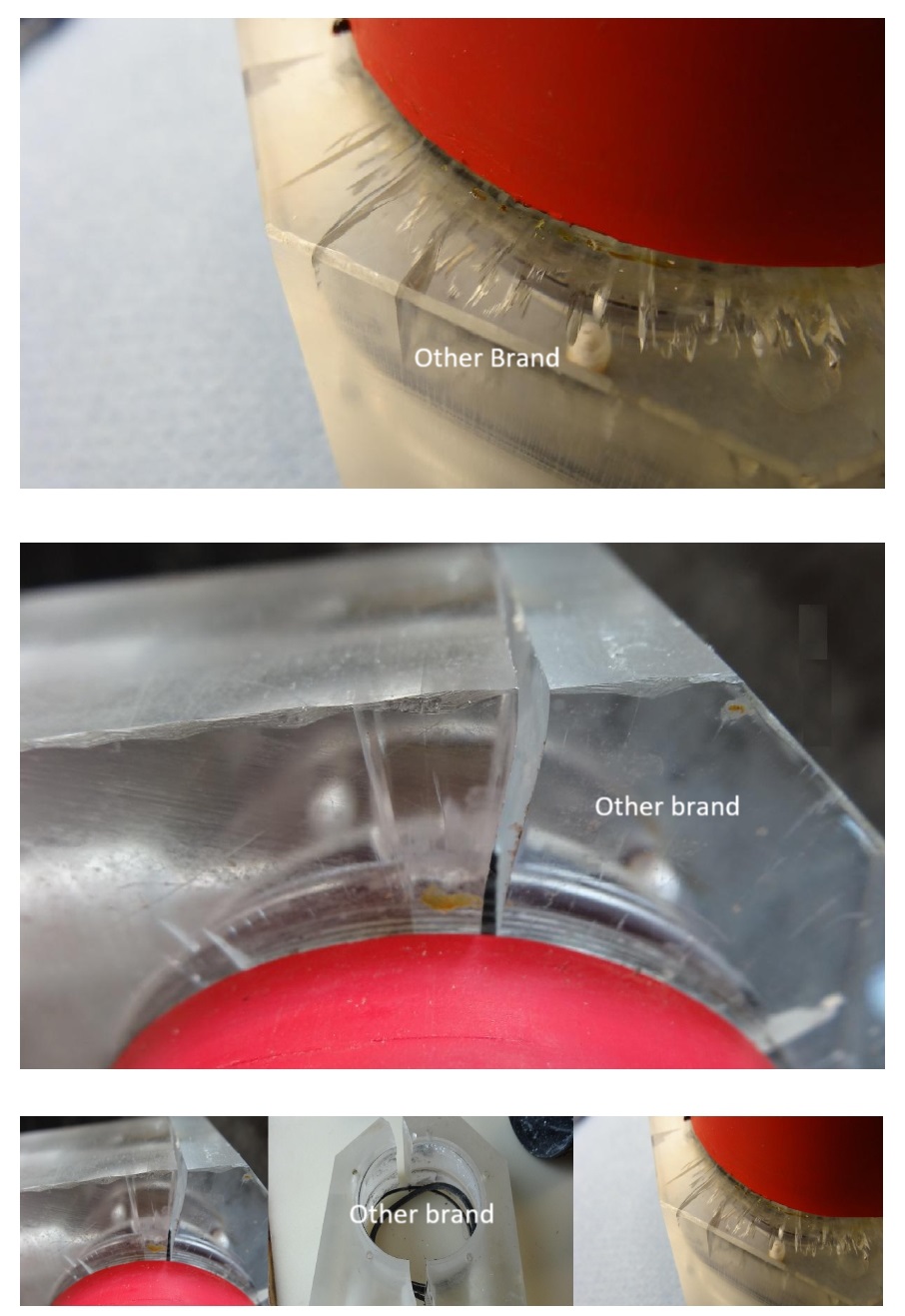

- It is understood that the vast majority of water electrolysis machine on the market are not suitable for mass production in factories. Most of the water electrolyzers on the market are flat-type, as their electrolytic plates, electrolytic membranes and electrodes cannot be cleaned entirely, resulting in: (a) interior of the electrolytic membranes gradually scaled and calcified; (b) PH value of the produced water gradually decreases; (c) The machine overheat, causing the machine to malfunction or burn down.

Results → Poor Quality → Production line stops and malfunctions → Waste of raw material water → the machine cannot continue to be used, the production line may hence be shut down → the water product doesn't meet the quality standards, which leads to consumer complaints and media criticizes → Business losses (including tangible materials, wages and intangible corporate reputations and stock price).

-

Therefore, if you want to launch functional water or ion plus functional drink products, you must plan the project with a intention of "must be successful". The owner must successfully operate sustainably, choose the right industrial electrolysis alkaline ionizing machine and equipment production line. Only in this way can we create a good niche and subsequent sustainable development for the company. Don't be greedy for small gains, so as not to lose big for small things.

Please write us about your feedback with your real experiences are very welcome. This email address is being protected from spambots. You need JavaScript enabled to view it.

1. Long time, Mass production, Automatic production technology

GA industrial electrolyzers are designed for mass production lines at bottled water factory. Each GA unit can independently manufacture 3 tons of alkaline ionized water per hour. The machine is equipped with unique industrialized cylinder electrode with patented automatic reverse wash system which will switch the electrode automatically, therefore, the acidic water will not be mixed with alkaline ionized water. The waste water will be automatically discharged by the waste pipe. The machine has a unique electrical structure, so the machine can be operated for a long hours of operation and mass production. The GA machines are equipped and have the following functions:

① Built-in PLC Computer Program

The machine operates automatically, the PLC program will store and automatically recording the operation. The operation mode of the electrolysis is adjustable according to the feed water quality which is easy to operate with stable quality.

② Electrolytic hour calculator and replacement alert function:

The electrolyzer has the hour calculator to show the operation hours which reminds the users to exchange the chambers regularly so that ensure production safety and quality.

③ Auto-proof device:

The power has a auto-protection device which automatically shuts off the power when over-current occurs.

④ Liquid sensor protection device:

When the water supply pressure is abnormal, the operation of the machine will be automatically shut off to avoid damage of components to machine.

⑤ Program auto reset function:

The built-in PLC device can change the electrolysis mode and recording as needed. When the machine go malfunctions, the program can automatically reset and operate normally.

⑥ Water-proof device:

The GA has a water-proof structure device to prevent damage on the electrode circuit or avoid accidents when the pipeline leaks.

⑦ Electrode protection device:

The electrode protection device protects the electrode to avoid leakage or cause accidents.

⑧ Six-stage current adjustment and other functions:

The current intensity can be adjusting according to the requirement of the feed water.

The GA electrolysis system is suitable for mass production and automatic production bottled water lines with stable quality and reliability.

Note: Experienced factory Manager understands that if the production line frequently breaks down or has poor quality, or stops production multiple times a month, the long-term cumulative losses of the factory may exceed the cost of the GA machine. This is because the owner still needs to pay wages, production line loss, and materials, etc. It also may even leads to problems such as unable to supply in a timely manner.

The unique patented backwash technology and automation system of GA electrolyzer can produce large quantities for a long time, ensuring stable quality and producing high-quality products. There is currently no identical or completely similar electrolysis equipment system in the world.

2. Efficiency is 3.14 times higher

GA's unique 360-degree and double-cylinder electrolytic cell that the surface of cathode is four times than anode. The electrolytic cell is round cell, so the water will flow smoothly. The electrode interval is averaged. The electrolysis efficiency 3.14 times higher than the flat type (Note: the circumference is 3.14 times than diameter in theoretical value). With instant electrolysis capability, it can produce high concentration of dissolved atomic hydrogen water with high concentration of alkaline ionized water with stable pH.

The cathode and anode of the flat cell have the same size of plate. The chambers need to be wrapped by the plastic outer, and the flow water in the tank will be turbulent during electrolysis, which is not stable. (For details, please refer to the cylinder type versus flat type comparison list).

3. The cell life of electrolytic chamber is some 6 times longer than the flat type

The GA industrialized double-cylinder electrolytic cell has the unique titanium-platinum surface treatment technology. The cell life of flat type is about 1000 hours (asking the user for the details). The cell life of GA is up to 6000 hours (guaranteed by Super Aqua) to ensure the production of food-grade alkaline ionized water. The life of the GA cylinder electrolyzer is about 6 times higher than the general flat type.

4. Green/ Saving Water Technology

GA unique industrial double cylinder electrolyzer produce at ratio of 75% alkaline ionized water and 25% of acidic ion water can be reproduce for ①high commercial value for beauty lotion. ② High-concentration of hypochlorous acid water which use for disinfection and sterilizing water for the washing, capping or CIP at bevereage plants, saving cost for the company. ③ Can be 100% filtered for feed water of the GA electrolyzer. There is no water resources are wasted.

Note:It is understood that the flat ionized water of flat machine, the ratio is 50%. So if you produce 20 tons of Alkaline ionized water per hour, then you would waste 20 tons of acidic water per hour. If 20 hours per day, then you need waste 400 tons of water in a day. Water consumption is some 12,000 tons of water per month. It consumes about 144,000 tons of water per year.

5、 Safe and Secure Products

The double cylinder cell used of GA industry has no need use a plastic casing to package the electrolytic cell. The customer has no need to worry about the plastic substance of PVC outer contaminating the alkaline ionized water. The GA machines manufacture food grade, safe and secure products.

The flat type electrolytic cell needs to wrap with the plastic outer casing. During the long hours electrolysis process the temperatures of chambers will be heating up which the high temperature will cause the plastic outer casing dissolving and deformed which causing PVC chemical substances contaminating the water and foarmful to consumers’ health.

6.、 Unique Delicious Water Tech

In general, the pH of 9 or higher ionized water could have the poorer taste. Super Aqua's unique electrolysis technology system has the alkaline ion will enter the cathode which the ionized minerals are good for human health. The taste of alkaline ionized water is mild, soft and delicious. Even when the pH is higher than 9.0, the taste of water is smooth and delicious. Repeated consumption of products by consumers are the guarantee the success of business. Super Aqua’s customer participated the famous Monde Selection bottled water competition in Europe, which won the gold medals twice. The quality of the product was highly recognized by consumers.

Note: In general, the water produced by the flat type electrolyzers have rough or poorer water taste.

7、Electrolysis Equipment Determines Customer’s Final Product

It is choice of the electrolyzer determines the quality of your final water product. Therefore, choice of the electrolyzer is a key to influence product sales performance.

GA technology and equipment can allow customers to gain a competitive advantage in the market and maintain a leading position in the market. Many of Super Aqua's customers are market leaders, such as Japan's Kirin Beverage, Taiwan Salt, Thailand's Ichitan, Vietnam's Fujiwa, etc.

8、Industry-Leading Patented Technology and Business Performance

Super Aqua team has more than 40 years of R & D, over 1,000 patented technical backgrounds, and is proud to be the global leader in electrolytic water technology. It is also the foundation for customers' products to lead the market and the guarantee of quality trust. The Super Aqua team has more than 30 years of commercial operation experience in the large-scale industrial alkaline ionized water electolyzer. Super Aqua is the best partner for customers in the electrolytic water business.

|

|

| Double Cylinder Titanium Platinum Chamber (3 chambers per set) | Flat type chamber, covered by plastic |

| Item | Golden Alkalizer (GA) | Other Brand | GA Advantages |

|---|---|---|---|

| Type | Industrial large double–cylinder electrolysis chamber | flat type chamber | Advantages of double cylinder electrolysis chamber |

| Chamber type | Industrial large double–cylinder electrolysis chamber

|

Flat type chamber

|

|

| Electrolysis efficiency |

|

|

|

| Material of the Chamber |

|

Note: In some areas, when electrolyzed water products were tested, it was found that the electrolytic cell material was poor and released harmful substances. |

|

| Out cage of electrolysis chamber | no plastic casing for GA's chamber |

|

|

| Service Life of electrolytic chamber | The service life is about 4,000 hours and up to 6,000 hours is possible (1-year warranty) |

The service life is about 1,000 hours. (Please contact the maker for more information on actual usage and conditions). |

The service life of GA electrolytic chamber is longer |

| Production | a single GA machine generates 3 tons per hour. |

Multiple generators The quality of electrolyzed water produced by a single electrolyzer is different because of the distinct efficiency of electrodes in each generator (80 generators totally). Difficulty in operation for a long period. |

|

| Mass Production |

|

|

|

| Sterilization to the Electrolysis Chamber |

|

interior of the chamber cannot be cleaned by hot water | Cleaning and sterilization to the interior of electrolysis chamber is available. |

| Alkaline/Acidic water ratio |

|

|

|

| Device for acidic water recycle |

|

The acidic water cannot be reused due to the device is too expensive. resulting in the waste of around 1500 Liters per hour |

|

| Automatic Production |

Each GA machine has three cylinder type electrolysis chamber, and each electrolysis chamber independently and switchable under control of the CPU's automatic system. Also, the auto system can automatically clean the electrolysis chamber. With the CPU auto control, the water flow rates is very steady and stable, hence to produce a stable PH water.

|

Each of multiple generators (80 generators) connected in series for production performs independently and has inconsistent backwash time causing difficulty in discharge of waste liquids. The continuous mass-production is probably unavailable. |

|

| Ion exchange membrane for electrolyze |

Unique membrane technology: Features: |

Use ion exchange membrane. disadvantages:

Weak voltage and current |

|

| Commercial Records |

|

No brilliant commercial records on high-quality production in beverage factory |

|

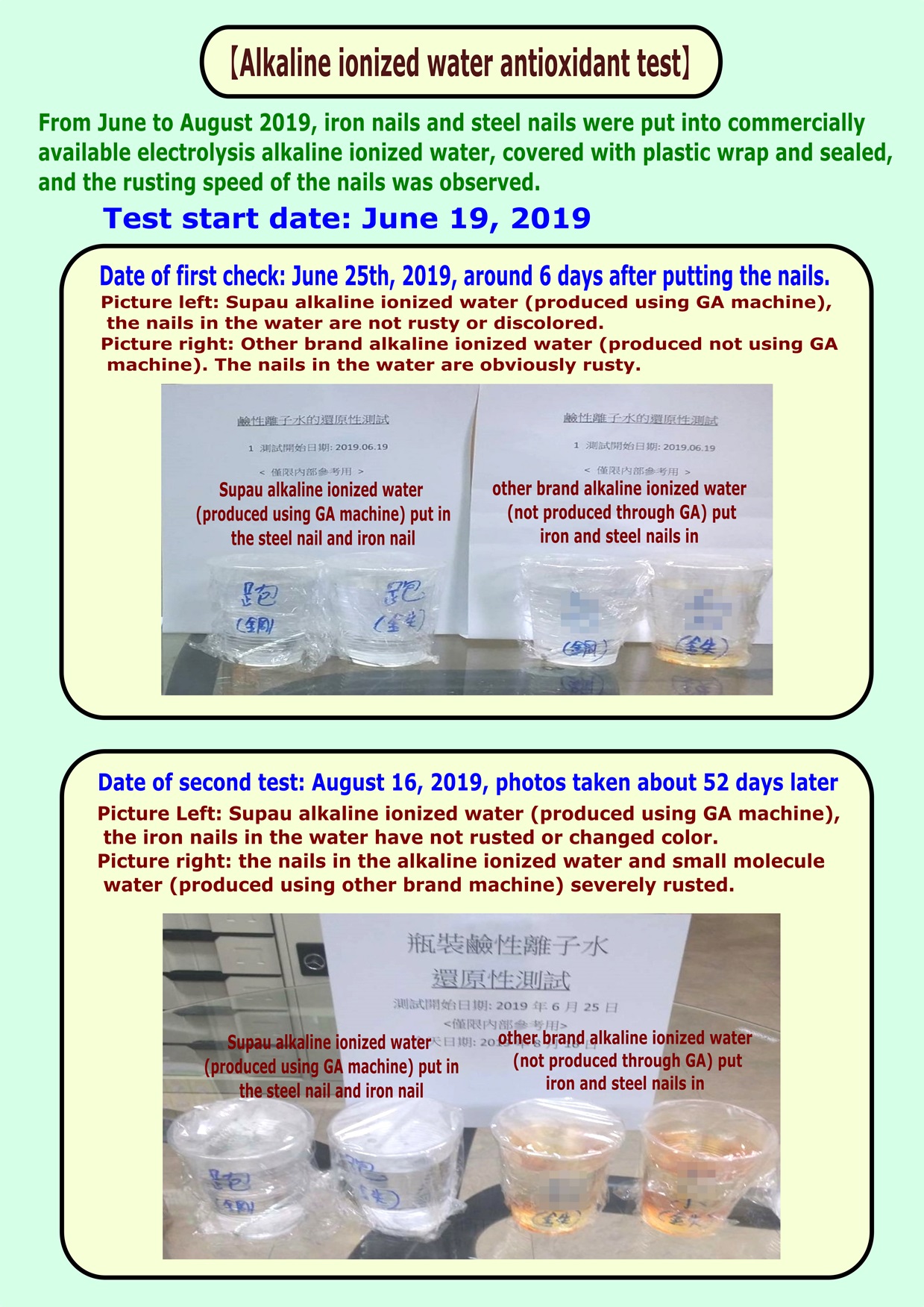

1. Anti-Oxygen

2. US Agent Mr. Alan Ogielve's witness

Entire text: Link

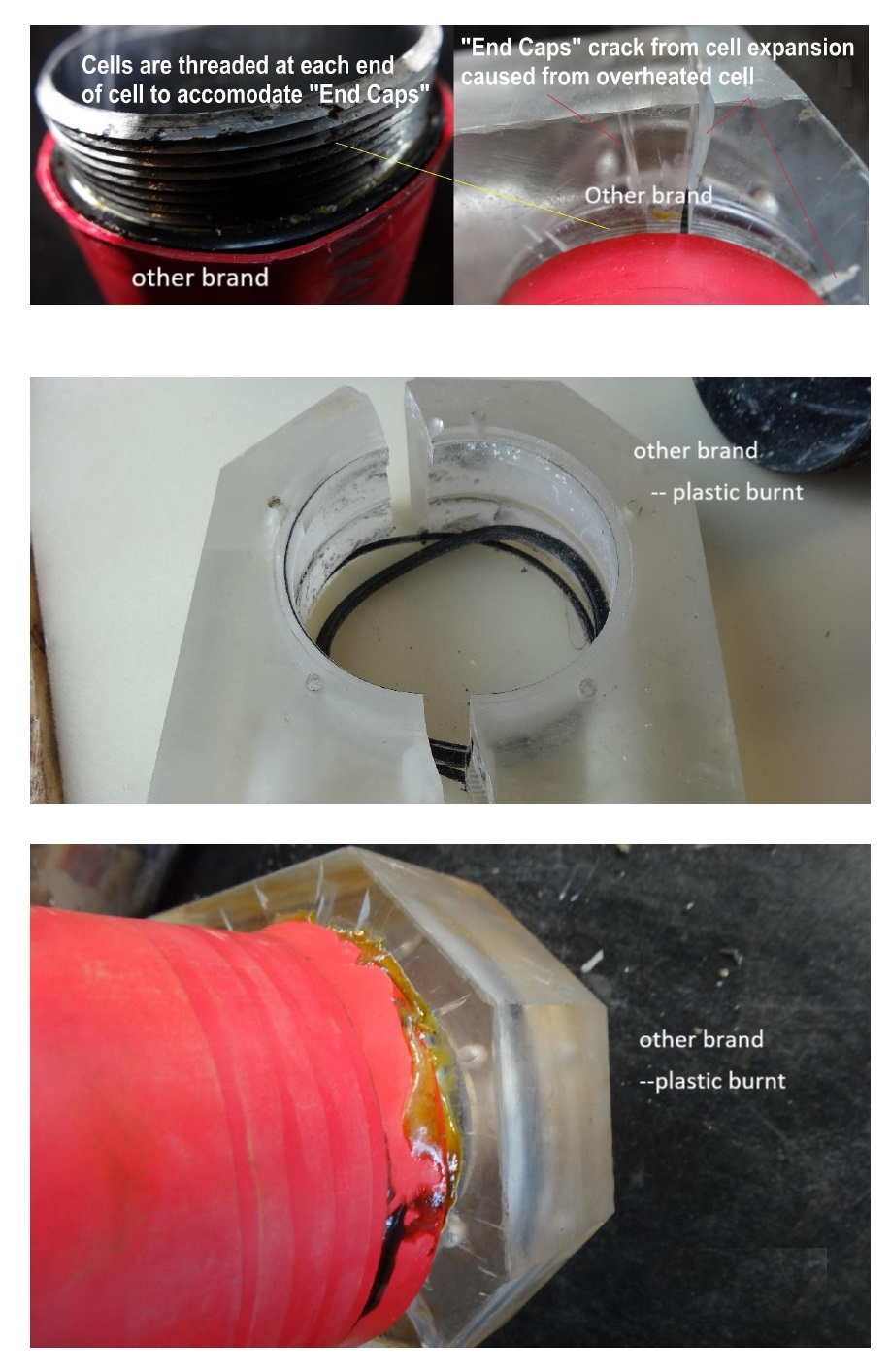

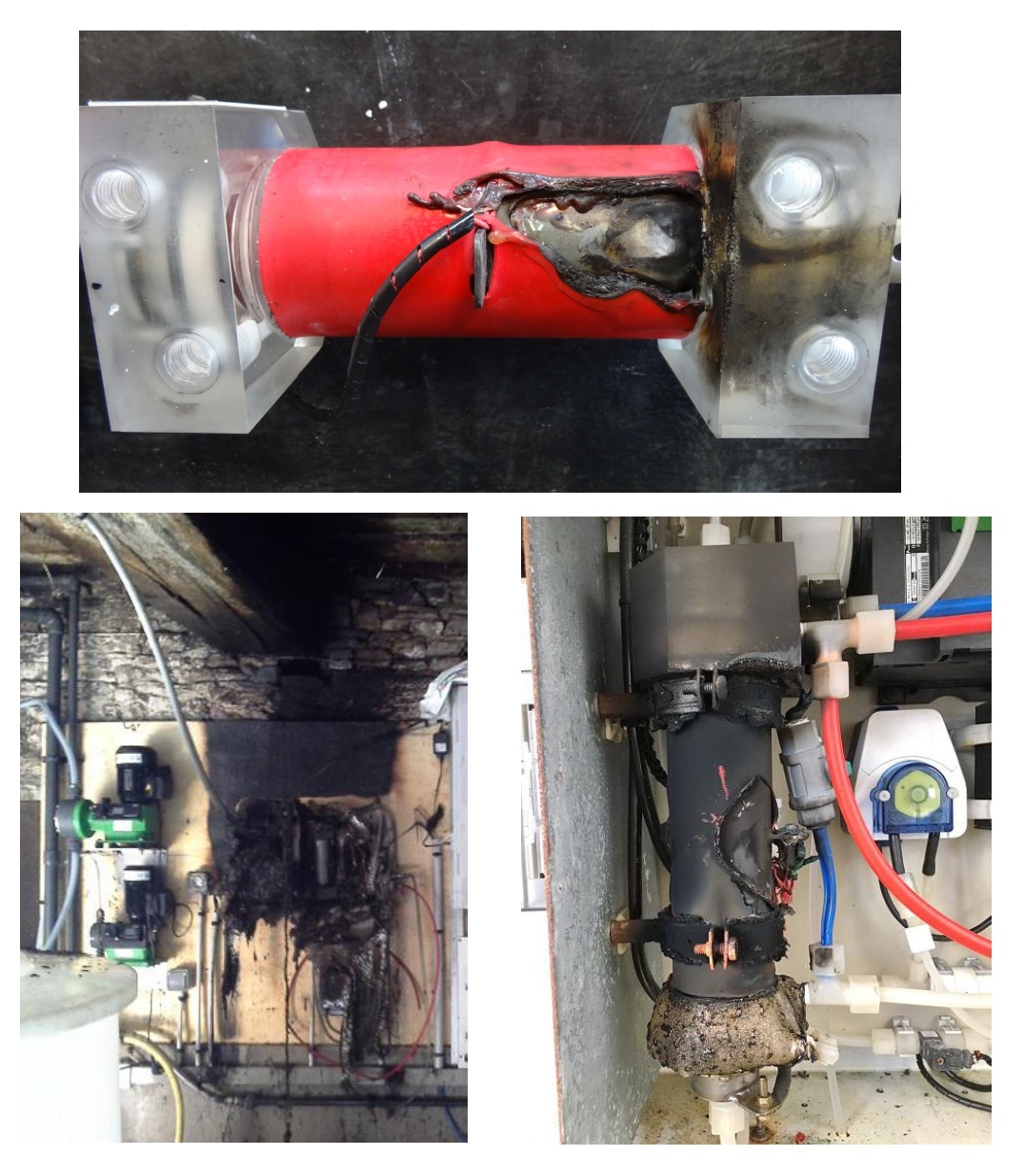

3. Photos of other brand's burnt electrolyzer

1). Other brand's electrolyzer and its electrolysis chambers burnt out due to overheating (see the photos below)!

(Upper images: other brand electrolyzer burnt due to overheating)

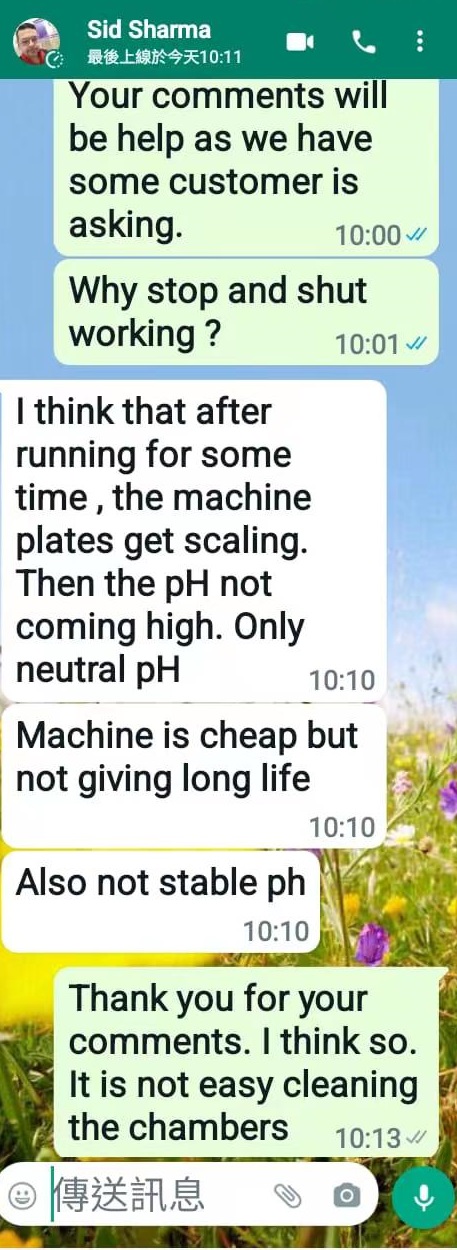

2). The Electrolyzer which is made in C Country: A certain brand of electrolyzer made in C country while after using a period of time, its electrolytic tank scaled, causing the pH value of the water to drop to the point where it could not meet the standard, and the pH only reached neutral.

Although that electrolyzer made by C country is very cheap, it cannot be used for a long time, and the pH value of the water produced is unstable (see the screenshot of the conversation below for details). The suspension of production will cause heavy losses to the company.

In addition, improper treatment of electrolytic plates may dissolve heavy metals and harmful substances, affecting consumer health.

3). A certain E brand electrolyzer doesn't provide after service, and No Refund even the machine fails the acceptance inspection

(please request our company for details)

4. Commercial Records in Customers' Factories

For more info, please visit our company's official site at the webpage "Performance"

and Youtube: Jane Super Aqua

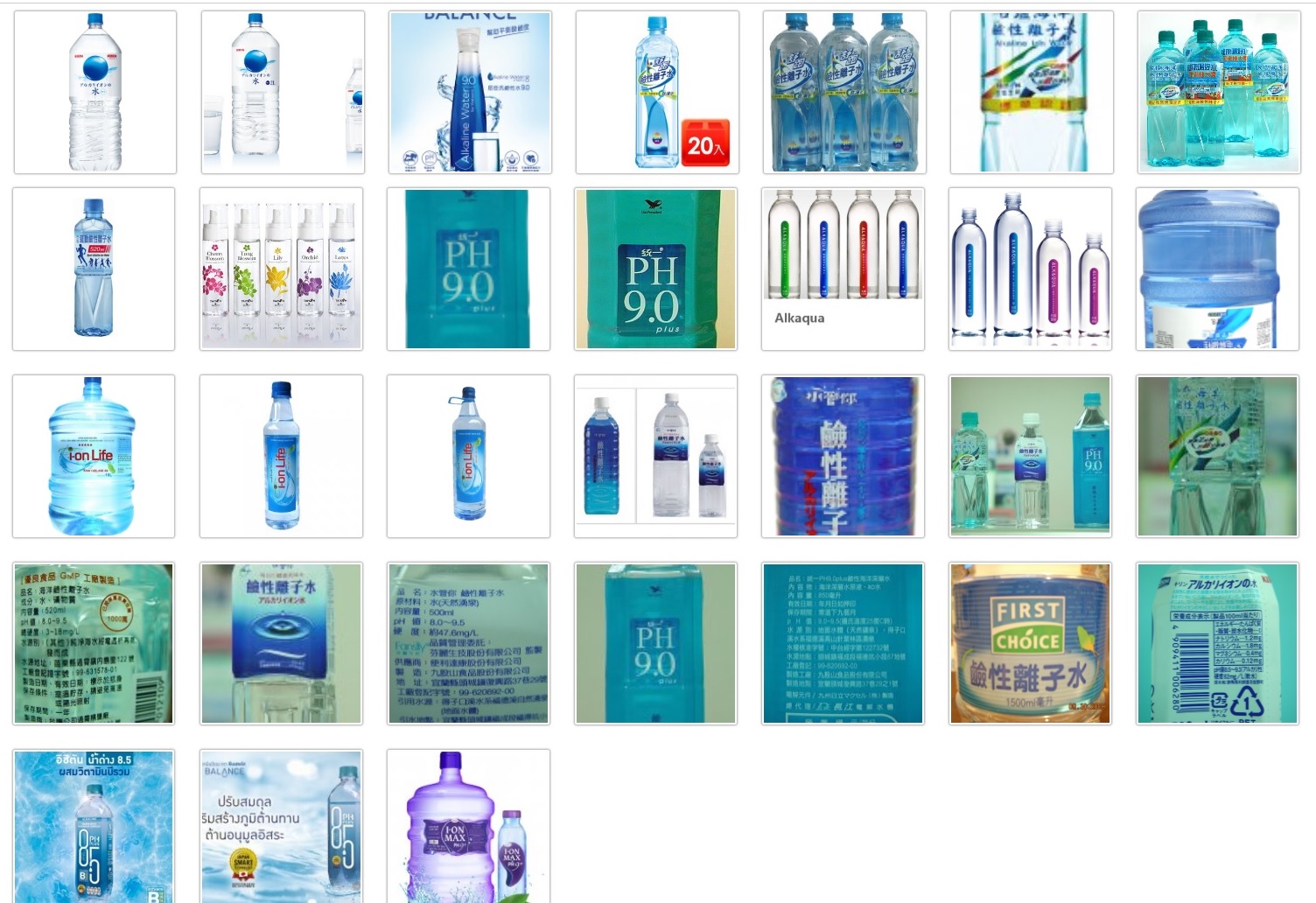

5. The bottled electrolysis alkaline ionized water products and the ion plus drinks which applying Chairman Okazaki's Technology

Details please visit our Official Webpage at https://www.superaquaholding.com/index.php/en/customers-products-en.html

Background of 1000 Patents

Superb background for electrolysis technologies and 1,000 patents in 40 years.

Read more

Golden Alkalizer(R) Technology and Merits

The unique technology for electrolysis alkaline ionized water and other functional water.

Read more

GA vs NDX

OMC (Okazaki Manufacture Co) had been the world leader of functional electrolysis water technology, who is recognized as some top technology in Japan even in the world, The technology was with some over 40 years’ R&D and 1,000 industrial patents.

Read more

Problem of using household Ionizer in Industrial production

Flat type chamber packed by plastic outer which long hour operating may cause leaking of water and outer shape changed.

Performance

Customer Cases

Our rich experiences in workshop practices & planning and modular producing operation systems are guarantees of customers’ trusts and successes. Super Aqua senior technical consultants and managers, who specialize in planning and practices of manufacturing systems for bottled alkaline ionized water (functional water) by their in-situ experiences in factories, are customers’ best partners in bottled functional water.

How to improve from NDX-XXXX

Technical Instruction:

How to improve the Design and Problems of NDX-3000?

So called alkaline ionized water electrolysis generator has the electrolytic chambers which use drinking water or artificial mixed water supplying the water from bottom and upflow into two rooms separately by the membrane.

English

English  繁體中文

繁體中文  简体中文

简体中文