|

| LEADER OF ELECTROLYSIS TECHNOLOGY |

Leasing program

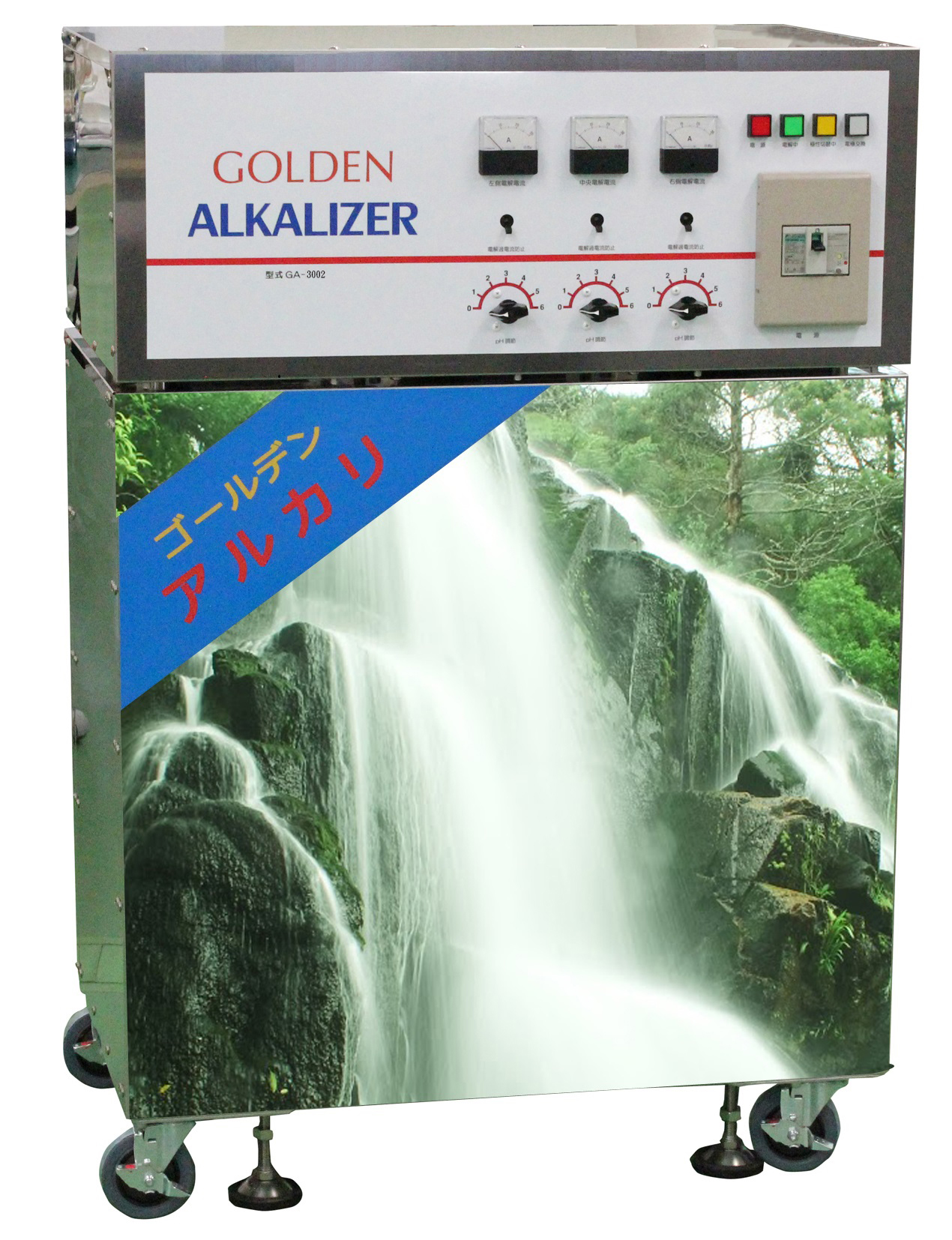

GA-3002 Golden Alkalizer Water Ionizer&Specifications

Huge Market, Easy Enter

Super Aqua

GA-3002 Golden Alkalizer Water Ionizer&Specifications

(Advance, Unique, Patented Technology)

Machinery Specifications

| Name: | Water Electrolysis Apparatus |

|---|---|

| Machine Number: | Golden Alkalizer GA-3002 |

| Ionized Water Production: | Continuous flow |

| Power Supply: | AC220V (3-phase) 50A 18KW |

| Overall Dimensions (mm): | Whole Unit: 908w x 696d x 1280h Power Unit: 908w x 574d x 360h Electrolysis Unit: 903w x 574d x 360h |

| Unit Weight (dry): | Approx. 275 KG (606 lbs.) |

| Water Pressure: | 2 KG – 2.5 KG / cm2 |

| Alkaline Ionized Water: | Approx. 3,000 L / hour |

| Acidic Ionized Water: | Approx. 1,000 L / hour |

| pH Levels: | Alkaline: 7-10 * Acid: 4-7 * |

| ORP Levels: | Alkaline: -100 mV ~ -300 mV * |

| Electrodes/chamber: | 3 units (round cell technology) |

| Electrode Cleaning Cycle: | Auto reverse wash.(Patent applied) |

| Chamber life: | One year or Approximately 6,000 hours |

| Electrolyzed adjuster: | Yes, 0-6 steps per the pH alkaline ionized water expected. |

| Auto shut off: | Yes, Floating sensor if water pressure is0.5Kg below. |

| Optional: | Surrounding equipment likely Water Tank, Control Box and System Piping etc... at client’s cost. |

| Warranty: | Lifetime warranty (On normal operation the parts and electrolysis chambers replacement at our cost) |

| Water Source: | To be informed |

| Environment Temperature Limits: | Normal temperature |

| Environment Humidity Limits: | Dry and Clean |

Remarks: * Depending upon the feed water.

Production Capacities

The GA-3002 Ionizer is capable of operating some 20 hours per day with stable of production is possible. Basically the bottling manufacture line operate either 8 hour or 16 hour shifts. These calculations based on an 8 hour shift, and either for the 16 hour shift. The 16 hour (2 shifts) will has the maximize profits.

GA-3002

| Per Hour | 3,000 L |

|---|---|

| Per 8 Hour Shift | 24,000 L |

| Per 16 Hour Shift | 48,000 L |

Per 20 day Month

| Per 8 Hour Shift | 480,000 L |

|---|---|

| Per 16 Hour Shift | 1,056,000 L |

To enable our clients to enter the Ionized Water business easily, the GA-3002 unit is available on a lease basis. The length of the lease is 3 years, and the machine lease deposit is required upon contracting. The lease fees is payable on a monthly basis to Super Aqua upon per the length of the lease.

During the lease period, we offered “Lifetime Warranty” plan which goes into effect when the unit has been installed and covers the ionizer parts for the length of the lease contract.

Upon per the 6,000 operational hours, the electrolysis chambers will be replaced at our cost.

The GA-3002 Machinery Deposit is $45,000/Unit. Shipping and taxes are excluded

The Lease Fees is @US$0.015 per Liter

Monthly Totals based upon

| Per 8 Hour Shift | $7,200 |

|---|---|

| Per 16 Hour Shift | $15,840 |

| Manufacturing time: | Average of 90 days |

|---|---|

| Shipping time: | Ocean Freight: average 4 to 6 weeks Air Freight: average 1 to 2 weeks |

Extra Fees: The Freight, taxes, duties, brokerage and any other fees payable at the port of entry.

“Your best partner for functional water business”

The Golden Alkalizer Industrial Electrolysis Machine has following merits:

- Mass production: Newest and largest single electrolysis machine globally.

- High electrolysis efficiency: Electrolysis efficiency is 3.14 times than flat type

- Auto Reverse Wash Technology (Patented)

- Auto manufacturing technology

- Electrolysis chamber exchange alert: Replacing timely for an outstanding production

- Long hour operation is possible: Up to 20 hours/day.

- Tasty water technology: Unique expertise gives healthier, mild and delicious

- Saving water technology: Save up to 500 L / hour than previous model.

- Abundant commercial records: Team excellency installation at plant with success

For inquires and details, Please contact:

Super Aqua International Co., LTD

Email: This email address is being protected from spambots. You need JavaScript enabled to view it., This email address is being protected from spambots. You need JavaScript enabled to view it.

The New Functions of GA-3000/GA-3002 Industrial Electrolysis Water Machines

The New Functions of GA-3000/GA-3002

Industrial Electrolysis Water Machines

According to Chairman of OKAZAKI, the designer of OMT (OKAZAKI MANUFACTURE TECHNOLOGY) who has remodeled the GA machines from the old model of machine and the GA new machine has equipment with the functions or devices as follows:

| √ | PLC System Installed (NEW) | Compared the relay cord of old model, The GA machine has the PLC (computer program), which able recording the machine operation data and adjusting the running mode which fit the feed water quality. |

|---|---|---|

| √ | Supreme high electrolysis efficiency | The electrolysis efficiency is some twice stronger than the old model (theory value) which easier to obtain the high pH of water expected. |

| √ | New Reverse Wash System-PATENTED (NEW) | For avoid acidic water leakage into alkaline ionized water in old model, the GA new model designated with new special reverse washing system. The acidic ionized water will not mix into alkaline ionized water tank for ensure the quality of alkaline ion aquatic productions. |

| √ | Auto Water Pressure Protect System (NEW) | The GA machine has equipped with automatic water pressure protection system, if the water pressure (Below 0.5Kg/cm) is abnormal then machine will auto shut off so that avoid caused malfunctions or transformer burn down. |

| √ | Over current automatic protection device | The machine has equipped with automatic over-current protection device to prevent over-current, damage to the machine. Seven electrolysis switcher (Stage 0 - 6 section), may adjust electrolytic current to fit water quality, producing the desired PH value of alkaline ionized water. |

| √ | Chambers Exchange Alert (NEW) | The GA equipped the new chambers exchange Alert Lamp, Upon the cell life is due the alert lamp will light up auto so that customer can be preparing exchanging the electrolysis chambers on time for ensure production quality. |

| √ | Protection device for electricity polarity (NEW) | GA machine has the protection device for electricity polarity and the GA machine installed 9 electricity connectors which customers may select the suitable connectors to fit the feed water quality so that obtain the pH of alkaline ionized water desired. |

| √ | Green water-saving technology | GA machine has green water saving technology which output of alkaline ionized water about 3 tons (3/4), acidic ionized water about 1 ton (1/4). More saving water than ordinary equipment. |

| √ | Water Proof Designs (NEW) | GA machines has the design of chambers leakage prevention so that prevent from any water leakage or malfunctions caused. |

| √ | Increase machine inner space | Simplify the machine internal lines & piping system, increase machine inner space for service jobs. |

For detail Please contact us:

Super Aqua International Co Ltd.,

superaqua168@gmail.com

English

English  繁體中文

繁體中文  简体中文

简体中文